Oxide Aluminum Solar Panel Frame Kit AA10 PV Aluminum Profile Border

Place of Origin: XIAMEN, China

Brand Name: FGSMADE

Certification: ISO 9001

Model Number: PFAPayment & Shipping Terms:

Minimum Order Quantity: 1000 sets

Price: Negotiable

Packaging Details: Carton or pallet

Delivery Time: 5~15 days

Payment Terms: L/C, T/T

Supply Ability: 300000 ~ 500000sets per month

- Information

- Description

- Video

- Downloads

Place of Origin: XIAMEN, China

Brand Name: FGSMADE

Certification: ISO 9001

Model Number: PFAPayment & Shipping Terms:

Minimum Order Quantity: 1000 sets

Price: Negotiable

Packaging Details: Carton or pallet

Delivery Time: 5~15 days

Payment Terms: L/C, T/T

Supply Ability: 300000 ~ 500000sets per month

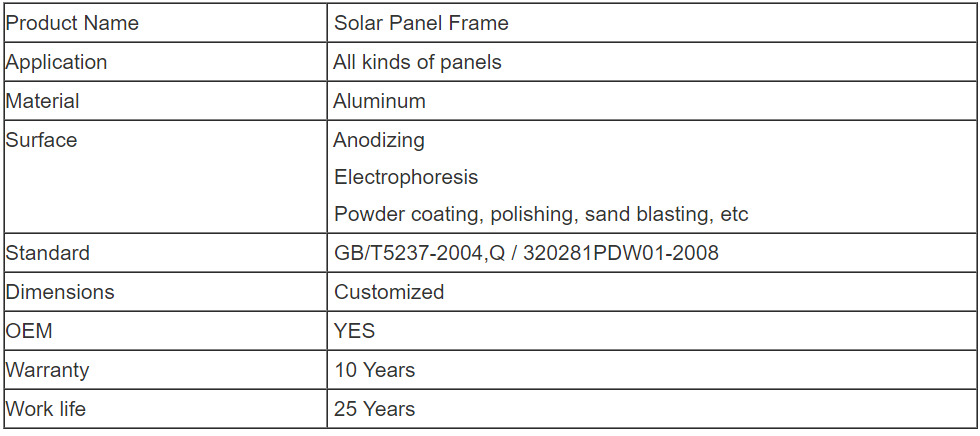

Name: Solar Panel Frame LP028 Material: Aluminum

Color: Silver Or Black Surface Treatment: AA10, AA12, AA15

Place Of Origin: XIAMEN, China Warranty: 25 Years

High Light: aluminum solar panel frame kit, oxide solar panel frame kit, aa10 pv panel frame

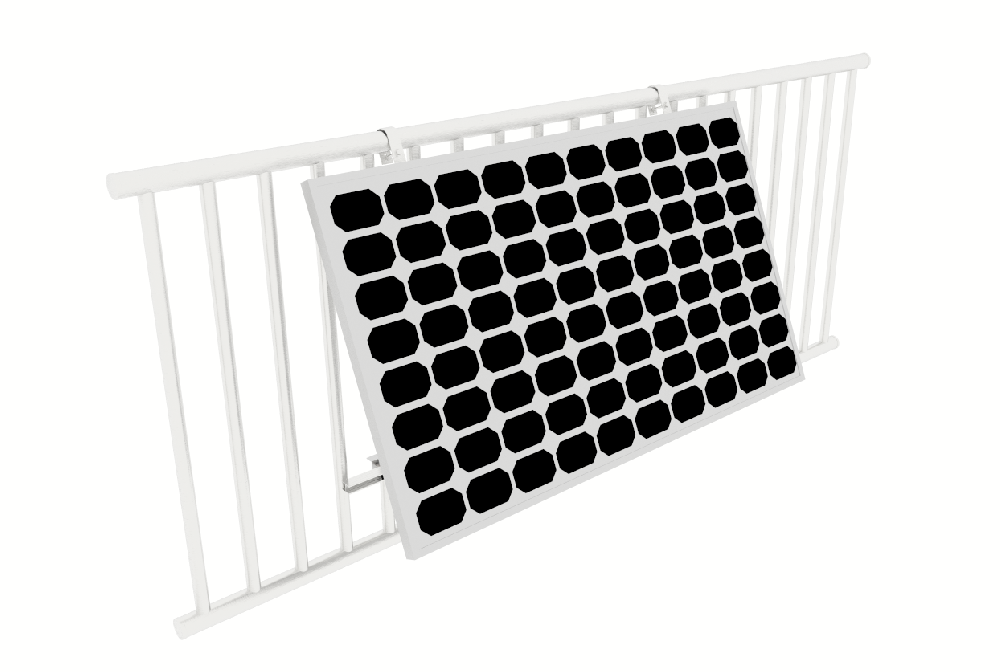

Solar Panel Frame Aluminum Profile Aluminum Solar Panel Border LP028

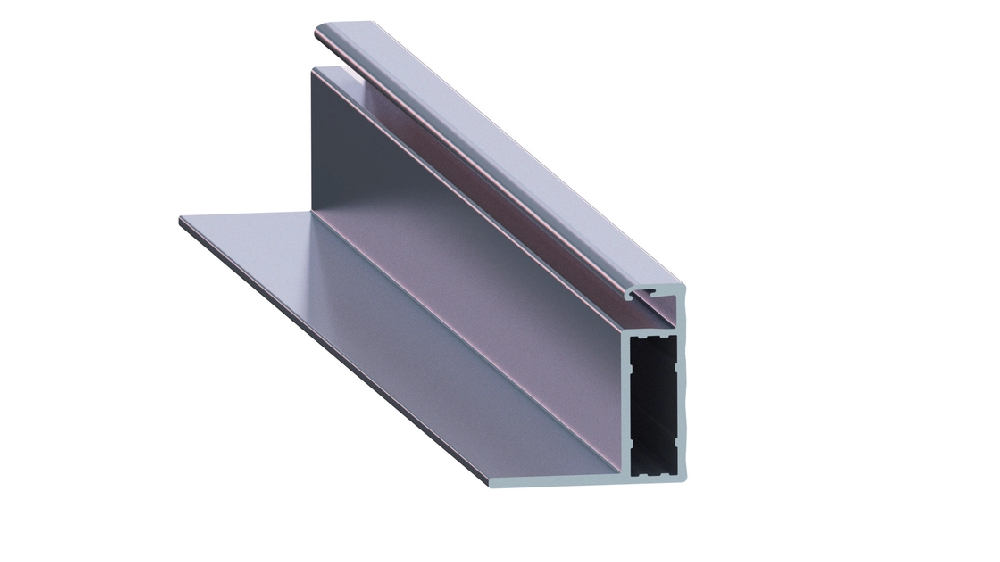

The cross-sectional shape of the solar frame is not regular, There are slots on it to facilitate the installation of the panel. The surface is silver matte, and some are black. The shape of the solar frame is extruded by the aluminum rod through the mold, and the surface effect is obtained by sandblasting + anodizing.

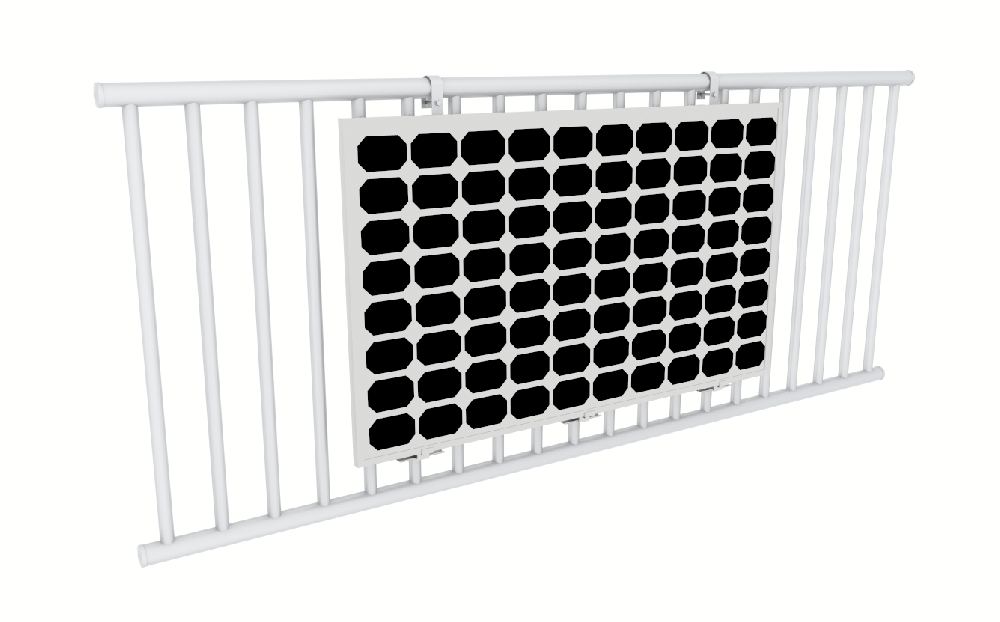

Generally, solar panels will be exposed to the sun and rain outdoors for many years, and the bad weather such as wind, snow and hail will also pose a threat to the solar power station. Therefore, the quality requirement of the aluminum frame of the solar panel is higher than that of the general industrial aluminum profile.

The selection of raw materials is very strict, and the content of each element must meet the following standards: si0.38-0.42%, mg0.53-0.57, Fe < 0.18%, the content of other elements must be within the range specified by the state, the purity of molten aluminum should be high, and the recycled materials can’t be used, that is, the anodized materials can’t be remelted to cast aluminum rods, so as to avoid small black spots and burrs or ash inclusions on the surface of profiles during extrusion, which will affect the surface quality of profiles, The surface of the profile will be blackened due to the unqualified mixed materials.

The extrusion die also needs to be polished carefully, especially the decorative surface of the aluminum frame, to avoid black lines and welding lines. The temperature and extrusion speed should also be strictly controlled during the extrusion process. Especially after the extrusion quenching treatment, the artificial aging time is well controlled, which largely determines whether the hardness of the aluminum frame material meets the standard. Generally, the hardness of aluminum profiles should be above 8hw, while the solar frame aluminum profiles should reach 12HW.

The frame aluminum profile after artificial aging shall be subject to sandblasting treatment. The sandblasting machine is made of carborundum, and the sand particles shall be uniform. In the sandblasting process, it is also necessary to prevent scratches.

The surface of the aluminum profile after sandblasting will form a matte effect. After that, it will be transferred to the oxidation workshop for surface anodizing treatment. The black frame material will be further colored. The oxidation time should also be specially controlled to increase the thickness of the oxide film. The oxidation thickness of ordinary aluminum profiles is generally 10μm, And the thickness of the oxide film of the solar frame profile should reach 15 μm.

The material after anodizing also needs to be coated to protect the surface of the material from being scratched during processing. The frame material after the film is applied can be transferred to the deep processing workshop for sawing, blanking, punching and riveting.

Each of the above processes shall be subject to strict inspection, and unqualified products are not allowed to flow into the next process. It seems that the production of solar photovoltaic modules is also very complicated and strict. Each set of finished frames packed by us is strictly inspected through n processes.