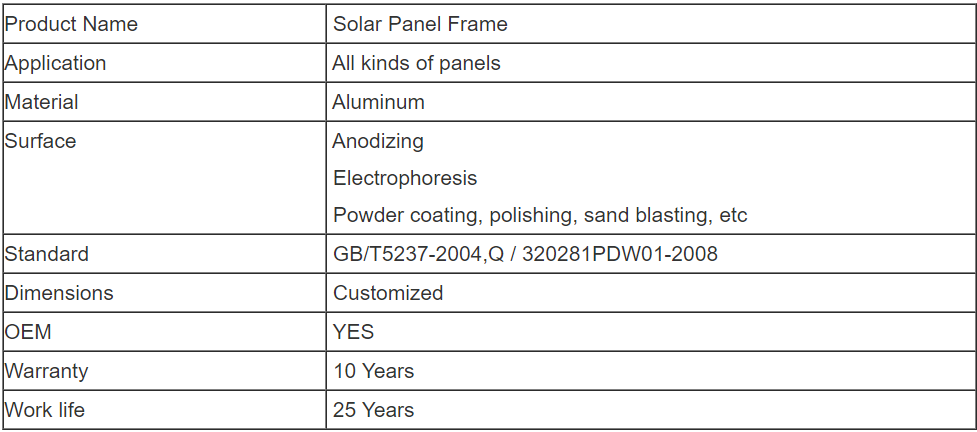

AA10 AA15 Aluminum Solar Panel Frame Anodizing

Product Details:

Place of Origin: Jiangsu, China

Brand Name: FGSMADE

Certification: ISO 9001

Model Number: PFAPayment & Shipping Terms:

Minimum Order Quantity: 1000 sets

Price: Negotiable

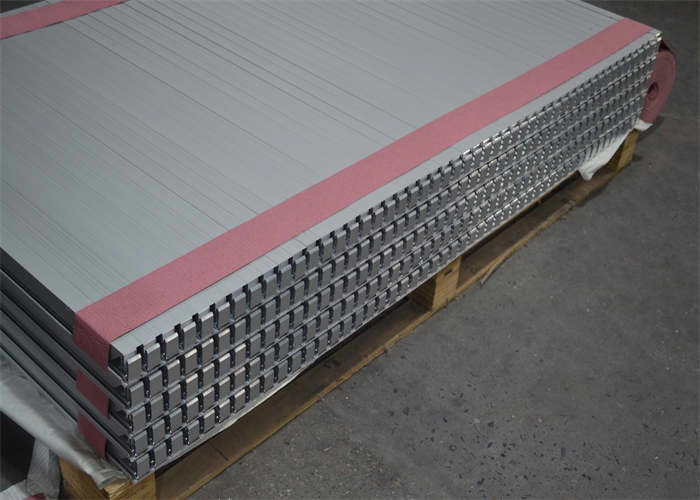

Packaging Details: Carton or pallet

Delivery Time: 5~15 days

Payment Terms: L/C, T/T

Supply Ability: 300000 ~ 500000sets per month

- Information

- Description

- Video

- Downloads

Product Details:

Place of Origin: Jiangsu, China

Brand Name: FGSMADE

Certification: ISO 9001

Model Number: PFAPayment & Shipping Terms:

Minimum Order Quantity: 1000 sets

Price: Negotiable

Packaging Details: Carton or pallet

Delivery Time: 5~15 days

Payment Terms: L/C, T/T

Supply Ability: 300000 ~ 500000sets per month

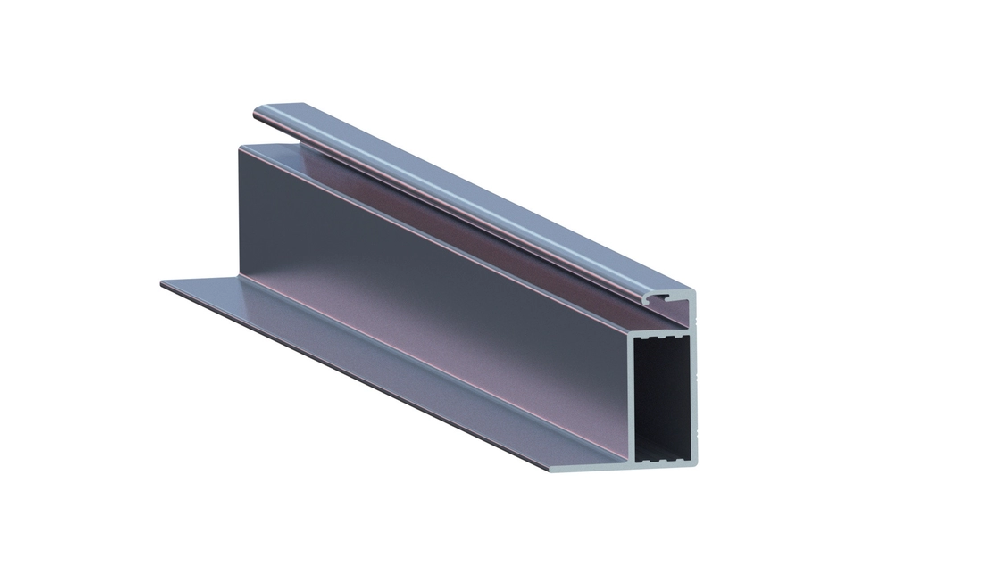

Name: Solar Panel Frame LP047 Material: Aluminum

Color: Silver Or Black Surface Treatment: AA10, AA12, AA15

Place Of Origin: Jiangsu, China Warranty: 25 Years

High Light: aa10 aluminum solar panel frame, aa15 aluminum solar panel frame, Anodizing solar aluminum frame

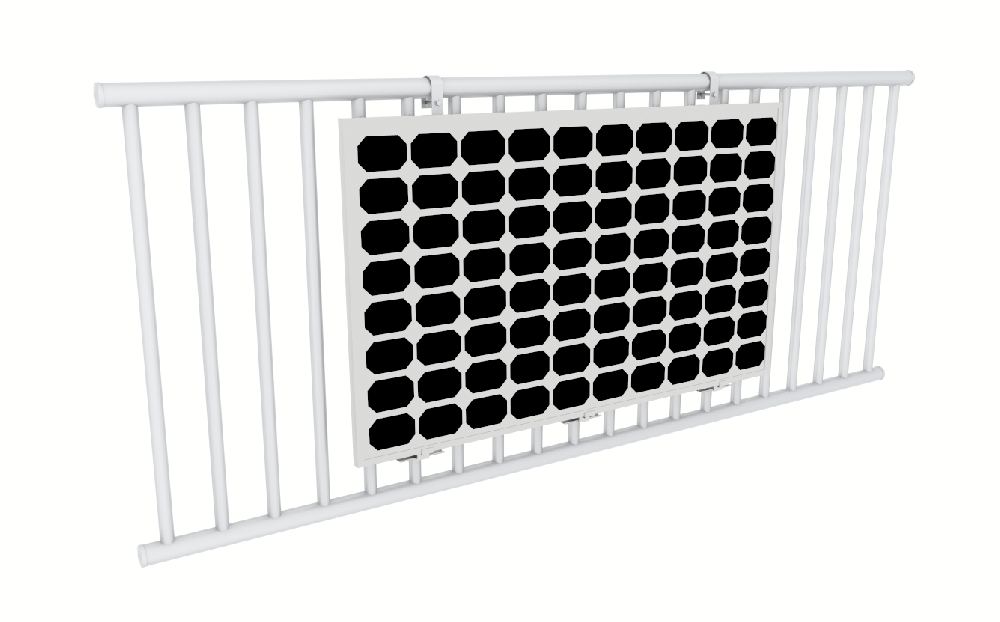

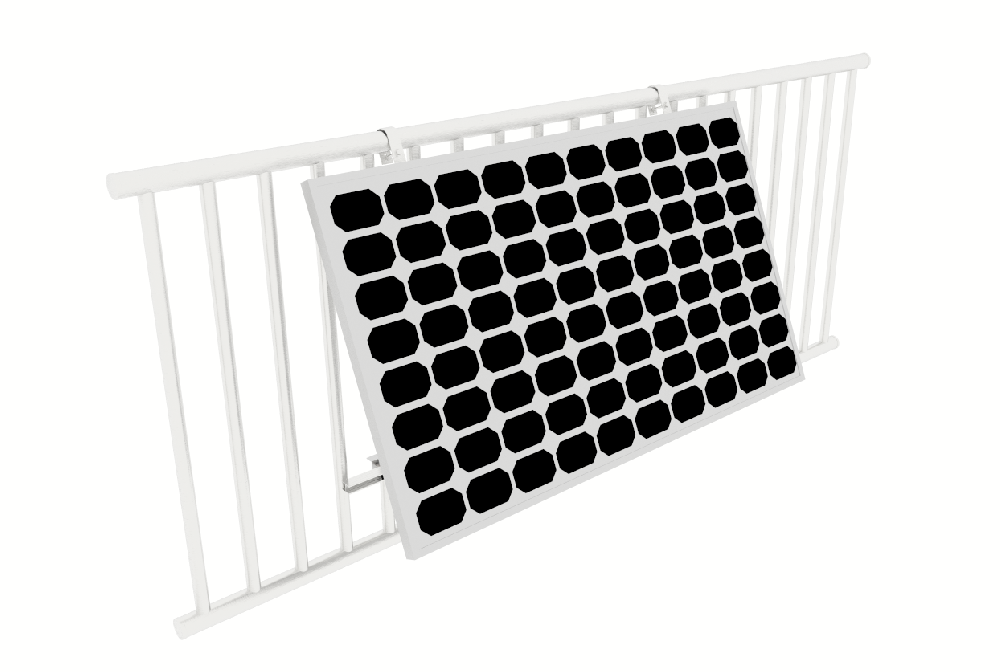

Solar Panel Frame Aluminum Profile Aluminum Solar Panel Border LP047

Aluminum alloy frame has always been one of the indispensable auxiliary materials for photovoltaic modules, mainly due to the advantages of aluminum alloy materials, mainly including:

1) Low density, the density of aluminum is about 2.7g/cm ³, A second light metal only higher than magnesium in the metal structure material;

2) It is easy to strengthen, and the strength of pure aluminum is not high, but it is easy to strengthen through alloying and heat treatment. To produce high-strength aluminum alloy, the strength can be comparable to that of alloy steel. Therefore, the elastic rate, rigidity and metal fatigue value are high, and it is not easy to deform, which can protect the solar panel well;

3) Good conductivity, the conductivity and thermal conductivity of aluminum are second only to silver, gold and copper, which is conducive to the installation and grounding of components;

4) High plasticity, good ductility of aluminum and its alloys, which can be made into various profiles by pressing, rolling or drawing;

5) Easy surface treatment, aluminum can be anodized and colored. After treatment, it has high hardness, good wear resistance, corrosion resistance and electrical insulation. Through chemical pretreatment, it can also be plated, electrophoretic and sprayed to further improve the decoration and protection of aluminum;

6) Corrosion resistance, strong oxidation resistance, and stronger corrosion resistance than steel;

7) Convenient transportation and installation. Even if the surface is scratched, it will not produce oxidation and will not affect the performance;

8) Long service life. The service life of aluminum alloy is generally more than 30-50 years. And the service life of the battery panel is 25-30 years, so it can fully meet the use requirements;

9) Beautiful appearance: the surface of aluminum alloy can be silver white, black, etc. after anodizing, which meets the aesthetic requirements;

10) Easy to recover, low melting temperature of aluminum, 660 ° С About, the waste is easy to regenerate, the recovery rate is very high, and the recovery energy consumption is only 3% of the original aluminum.

Technical Data

AA10 AA15 Aluminum Solar Panel Frame Anodizing