Classification of photovoltaic brackets

2023-12-20

Photovoltaic mounting system can be divided into fixed, tilt-adjustable and auto-tracking three categories, and their connection methods generally have two forms of welding and assembly. The fixed bracket can be divided into roof type bracket, ground type bracket and water type bracket. Automatic tracking bracket is divided into single-axis tracking bracket and dual-axis tracking bracket.

1.Fixed bracket

Fixed bracket is also called fixed tilt bracket. After installing the bracket, the inclination and orientation of the components cannot be adjusted. Fixed bracket is divided into roof type, ground type and water type.

(1) Roof type bracket

Roof bracket is generally divided into three categories: color steel roof bracket, sloping roof (tile roof) bracket and flat roof bracket. Color steel plate roof bracket mainly consists of color steel plate fixture or fixed parts, rail (beam), component pressure block, rail connectors, bolts and washers, slider nuts and so on. Pitched roof bracket mainly consists of roof fixing hooks, guide rails (beams), component presses, guide rail connectors, bolt washers, nut sliders and so on.

The above two kinds of brackets generally use finished C-beam or aluminum alloy as the main supporting structural parts, which has the advantages of fast assembly and disassembly, no welding, even anticorrosion coating, good durability, fast installation and beautiful appearance. Flat roof bracket is similar to the structure of ground type bracket, generally using concrete counterweight block as the bracket foundation, and try not to damage the waterproof layer of the roof surface, with flexible structure and convenient installation.

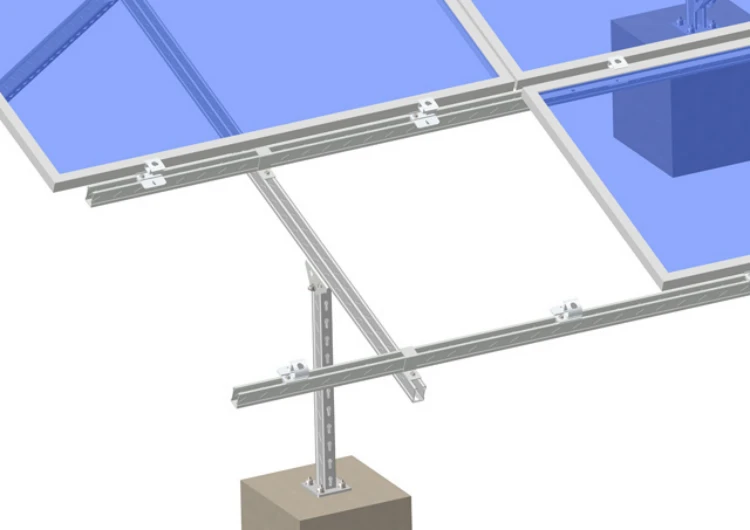

(2) Ground type bracket

Ground mounting system is divided into three categories: single column bracket, double column bracket and single ground column bracket. Single-column bracket relies on a single row of column support, and each unit has only a single row of bracket foundation. Single-column bracket is mainly composed of column, inclined support, rail (beam), component pressure block, rail connectors, bolt washers, nut slider, etc. The column is made of C-beam, H-beam or square steel pipe. Single-column bracket can reduce the amount of land construction and is suitable for areas with complicated topography and terrain. Double-column bracket is in the form of front and rear columns, which mainly consists of front column, rear column, inclined support, guide rail (crossbeam), rear support, component pressure block, guide rail connector, bolt washer, nut slider, etc. The columns are made of C-shape steel, H-shape steel, square steel pipe or round steel pipe according to the size of the square array, and the other components are made of C-shape steel, aluminum alloy, stainless steel, etc. according to the needs. The double-column bracket has even force, simple processing and production, and is suitable for areas with relatively flat terrain.

(3) Water surface type bracket

With the continuous promotion of distributed photovoltaic power generation projects, making full use of the sea, lakes, rivers and other water surface resources to install distributed photovoltaic power stations, the implementation of new forms of photovoltaic agriculture, such as fishery and light complementation, is another way to solve the problem of photovoltaic power generation is limited by land resources. The surface type bracket generally has two kinds of floating type and column type, the floating type bracket is caused by two parts of the float and bracket. The float is made of high-strength materials and has a one-piece design with good stability and strong impact resistance, which can effectively prevent the damage of PV modules caused by various water currents and gusts of wind. The bracket is generally made of stainless steel, aluminum alloy and other materials with strong corrosion resistance. Column type stent and ground type stent structure is more or less the same, only the column is longer, to ensure that the stent exposed to the water surface, at the same time, the column material should be selected to withstand long-term corrosion resistance in the water immersion.

2.Tilt adjustable bracket

The structure of tilt-adjustable bracket is similar to that of fixed bracket, but it has one more adjusting mechanism than fixed bracket, so that the tilt angle of the bracket can be adjusted manually. Adjustable mechanism has a staggered and continuously adjustable, staggered generally set to 2 ~ 3, a year according to the seasonal adjustment 2 ~ 3 times; continuously adjustable can be adjusted as often as needed. In order to facilitate the tilt angle adjustment, a single bracket should not be installed on too many components, usually the number of components installed to constitute exactly one or two strings. The tilt angle adjustable bracket has push-pull rod type, arc type, jack type and hydraulic rod type.