How much do you know about photovoltaic array basics?

2023-12-19

Photovoltaic array foundations mainly include concrete embedded parts foundations, concrete weight block foundations, spiral ground pile foundations, directly embedded foundations, concrete prefabricated pile foundations, ground anchor foundations, etc. These types of foundations have the advantages of being stable and reliable, and can be selected and applied according to the design and installation requirements of the power station, the geological soil conditions of the construction site, and the type of roof structure.

1.Concrete embedded part foundation

Concrete embedded part foundation is a foundation form with a wide range of applications. It is also the earliest traditional foundation form used in photovoltaic arrays. It is an independent foundation set under the front and rear fixed columns of the photovoltaic bracket. Concrete is poured on site, and embedded steel plates or embedded bolts are poured into it. The cross-section of this foundation can be made into square, circular, etc. Sometimes, in order to solve the problem of low bearing capacity of the surface soil at the power station site, a long strip foundation with front and rear column foundations integrated into one can also be made.

The advantages of concrete embedded parts foundation are wide application range, reliable force bearing, and no need for special machinery for construction. The disadvantages are large amount of earthwork excavation and backfilling work, long construction period, damage to the surrounding environment, and a large amount of soil will be left in the land in the future. Waste and construction debris.

2.Concrete counterweight block foundation

Concrete counterweight block foundation is often used together with embedded foundations in the construction or renovation of rooftop photovoltaic power generation systems, which can effectively avoid or reduce damage to roof waterproofing layers and other structures.

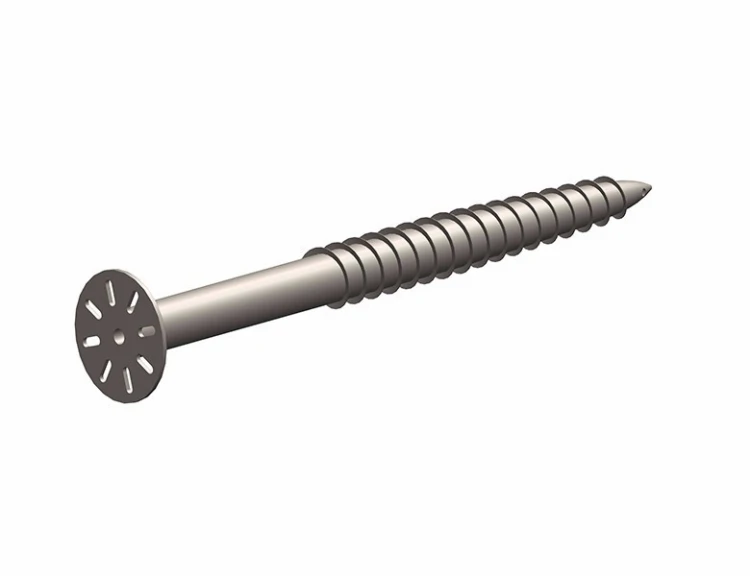

3.Spiral pile foundation

Spiral pile foundation is a form of photovoltaic support foundation that has become increasingly widely used in recent years. Spiral piles are made of hot-dip galvanized steel pipes with spiral blades. The blades can be large or small, continuous or intermittent. Continuous welding is used between the spiral blades and the steel pipe. Common spiral ground piles are shown in Figure 6-3. Their lengths are 0.55m, 0.7m, 1.0m, 1.2m, 1.6m, 1.8m, 2.0m, 2.7m and other specifications, and their diameters are 60mm, 65mm, 76mm, 89mm, 114mm, 168mm, 219mm and other specifications, the top has tubular, flange-shaped, U-shaped fork, square tube, cylindrical and other shapes, which can be selected according to needs. The upper part of the spiral ground pile foundation is exposed to the ground, and the height of the bracket can be adjusted according to the terrain. It is connected to the bracket columns through bolts. The construction tools for spiral ground piles include electric pile drivers, and the construction machinery includes spiral ground pile drilling rigs.

Spiral ground pile is a new type of foundation construction method. This method does not require excavation of the land and prefabricated concrete. It only needs to use special tools or special machinery to directly tamp or drill into the ground. Compared with the traditional concrete foundation, it has the characteristics of simple installation, convenient and fast, saving time, effort and materials, making the foundation The installation time is shortened, the construction cost is reduced, and it can be moved and recycled anytime and anywhere. It can protect the site vegetation to the maximum extent and has no pollution to the land and environment. After the system is dismantled at the end of its life, the foundation can be quickly dismantled together, leaving no waste in the land. Leave things behind and the site can be easily restored to its original appearance. 4.Directly buried foundation

4.Directly buried foundation

Directly buried foundations are also called cast-in-place pile foundations. Directly buried foundations are the simplest to construct. They are constructed by digging holes on site and pouring concrete on site. The channel steel or steel pipe is prefabricated before the concrete solidifies. Just insert the piece directly into the hole. While compacting the concrete, adjust the height of the foundation prefabricated component plane as needed. Although the construction process of directly buried foundation is simple, compared with spiral ground piles, the construction speed is slower and the construction period is longer. Since the direct-buried foundation does not require high concrete strength levels, the cost is lower. Directly buried foundation piles have no squeezing effect on the surrounding soil and have higher requirements for the self-reliance of the on-site soil. Therefore, whether to use directly buried foundations requires preliminary geological survey tests. Loose sandy soils and hard gravel soils Stone and pebble soil layers are not suitable for direct buried foundation construction. Loose sandy soil layers can easily cause hole collapse, while hard gravel and pebble soil layers can make it difficult to open holes.

5.Concrete precast pile foundation

Concrete precast pile foundations are generally made by professional manufacturers. The cross-sectional dimensions are generally 200mm×200mm square or φ300mm round. Steel plates or bolts are reserved on the top to facilitate connection with the support columns. The bottom is generally made into a pointed shape to facilitate construction. Drive or press into the soil. Precast concrete piles have the advantages of regular pile body, good pile body quality, strong corrosion resistance, simple and fast construction, and the cost is slightly higher than that of directly buried foundations. Compared with spiral ground piles, concrete precast pile foundations have relatively larger bottom and side areas, so it is easier to obtain greater structural resistance under the same geological conditions, and the cost is slightly lower than spiral pile foundations. However, during the construction process, the pile top elevation is not easy to control, and the construction technology requirements are relatively high.